Masked-Up and Ready for Class

With smaller class sizes and built-in safety measures, COCC prepares to offer 25%

of its curriculum in-person this fall

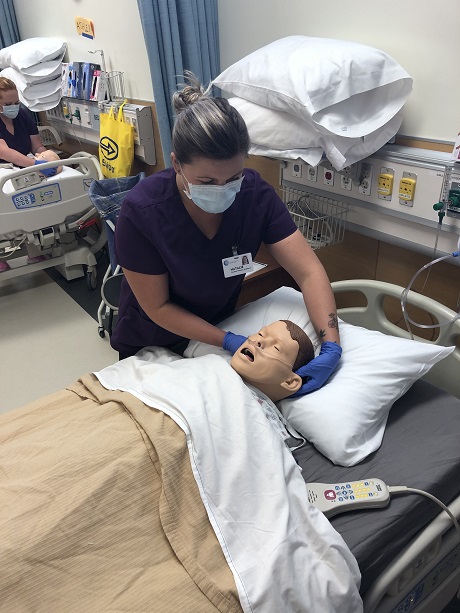

Nine nursing assistant students in a Central Oregon Community College (COCC) classroom

watch as the image of an oxygen mask appears on the classroom’s projector screen.

Instructor Vicki Thomas, mostly concealed behind a lively, rainbow-hued face covering,

is providing an overview of breathing therapy for the morning lecture. She walks her

students through the basics of applying the device to patients.

“You can’t eat or drink with a mask on,” she said, describing its limitations. Then,

pausing for effect, she turns to her students, all seated apart from one another.

“Do we know that? Yes, we do,” she added amid a dash of laughter, everyone masked-up

for COVID-19 precautions.

Like everything else these days, in-person learning is adapting to a new environment.

For these nursing assistant students, on week two of their summer term program, the

measures have already become routine.

Masks are mandatory in all buildings. Each class begins with a dab of hand sanitizer,

with dispensers located at both the building entrance and just inside the classroom

door. At the start of the day, and after their lunch, students have their temperature

taken with a non-contact digital thermometer. They’re asked about their health status.

They share any travel history.

Normally open to 18 students, this particular class is pared down to nine. Blue tape

marks an “X” on the desks that are off-limits for distancing purposes. At the end

of the lesson, students dutifully clean their workstation with a disinfectant wipe,

then head down the hall for the day’s lab portion. It’s all very matter-of-fact.

“It’s a normal part of the process,” said student Shonna Cunningham, referring to

the typical sterile expectations in the health care field. To that end, as every student

enters the lab — a mock hospital wing where mannequins are forever slumbering in hospital

beds — they head to a sink and scrub up. For many folks these days, obsessive handwashing

is a new routine. For health care workers, it’s business as usual.

Following state guidelines, and built around safety protocols and a smaller-sized

format, on-campus learning options at COCC, for fall term, will include about 25%

of the college's academic offerings. Some health care training, such as for nursing

and nursing assistant students, never veered from in-person learning. The state enabled

those fields to carry on, though with some adjustments. Other programs needed to retool

for the times.

The college’s automotive technology program, for instance, was back in operation this

summer, returning to the Bend and Redmond campuses after going on hiatus to best implement

COVID-19 precautions.

“We went from 20 per class down to 15,” explained Paul Pelly, director of the program,

outlining the modifications. Before students can go under the hood or step beneath

a vehicle lift, there are safety steps. “We’re taking temperatures of every student

and faculty,” he said. Having large, open training areas helps to keep things safe.

So does the eye protection that students normally don. Other precautions, such as

wearing rubber gloves, are now mandated.

There are specific access points as well. “We locked down the building,” he said,

explaining that only students for the class of the appointed timeslot are allowed

in. When arriving, they ring a bell, entering through a designated door; they exit

through a separate door. “When they grab a tool they have to sanitize it before they

bring it back to the tool room,” Pelly added.

Paola Santacruz, who’s completing her Master Automotive Technician Certification this

year, says that she was eager to return to campus. “There was no hesitation returning

to school,” she said. “The instructors have made it a safe learning environment. Everyone

has been working as a team to keep the school a secure area.”

Over at the Redmond campus’s Manufacturing and Applied Technology Center, Joe Huddleston

watches as the welding booths glow with action. The manufacturing program now has

20 in-person courses that are up and running.

“We actually found ourselves in a unique situation as all of our machines in the machine

shop are at least six feet apart and the weld booths are also six feet apart,” the

assistant professor said. A byproduct of welding, he pointed out, actually helps combat

the coronavirus: “The function of welding creates ultraviolet light, which helps to

keep the virus at bay.”

The shop is set up with an entrance and an exit so students don’t pass each other

coming and going. Their classes are split into smaller groups. “One for days and one

for nights, and limited enrollment, to keep us at 28 people in the shop at one time,

and no more,” he added.

Fall term begins on September 21. Get started today by calling 541-383-7700.

By Mark Russell Johnson, COCC Marketing and Public Relations